Meeting the demands of a constantly changing market is no easy feat. Using additive manufacturing technology to develop and maintain a competitive edge provides businesses with adaptability, scalability, and innovation. The ability to stay one step ahead of competitors is of the utmost importance for any business. In the face of unpredictability in demand and supply chains, being able to scale production as needed is rapidly evolving into a critical business advantage.

India, a burgeoning startup hotspot, could cultivate 3D printing's various benefits. The subcontinent's 3D printing sector, on the other hand, is still in its infancy. India's emerging entrepreneurs could use 3D printing services to scale their firms, taking advantage of the startup culture's boom over the last decade. In recent years, 3D printing has gained traction in the country. The government has launched several initiatives to encourage young innovators and entrepreneurs to adopt AM technology.

According to government statistics (Livemint), India's 3D printing market shows an annual growth of 20%. From $20 billion in 2020, analysts project a considerable increase in 3D printing to $37.2 billion in 2026. Automotive, electronics, healthcare, and aerospace are among the industries that will benefit most from this technology.

If the government announces some incentives, the National Strategy on Additive Manufacturing, which aims to add $2 billion–$3 billion to India's GDP by 2025, is likely to give a massive boost to the undefined 3D printing industry and make India a global centre for design, materials, and manufacturing of 3D printers. This leads us to a look at some of the future trends in 3D print solutions in India that will bring a massive transformation in this field.

1. Vocal for local: Indian officials have been promoting the indigenous 3D printing industry extensively through tax breaks and subsidies. Businesses can expect India-made 3D printers to hit the market in the upcoming years. India's 3D printers will be cost-effective while offering top-of-the-line features. Small enterprises do not need to worry about delivery time or extra costs with locally produced printers. This technology will help companies cut their overhead expenses while reducing production costs.

2. Cultivating 3D printing in research and development: 2022 will see more applications of 3D printing in research and development in India. For instance, it will, among other things, assist engineers in building multiple prototypes, making alterations based on design testing, and learning more about product testing before finalising production plans. In addition, as research and development become economical, India will launch various new items on the market.

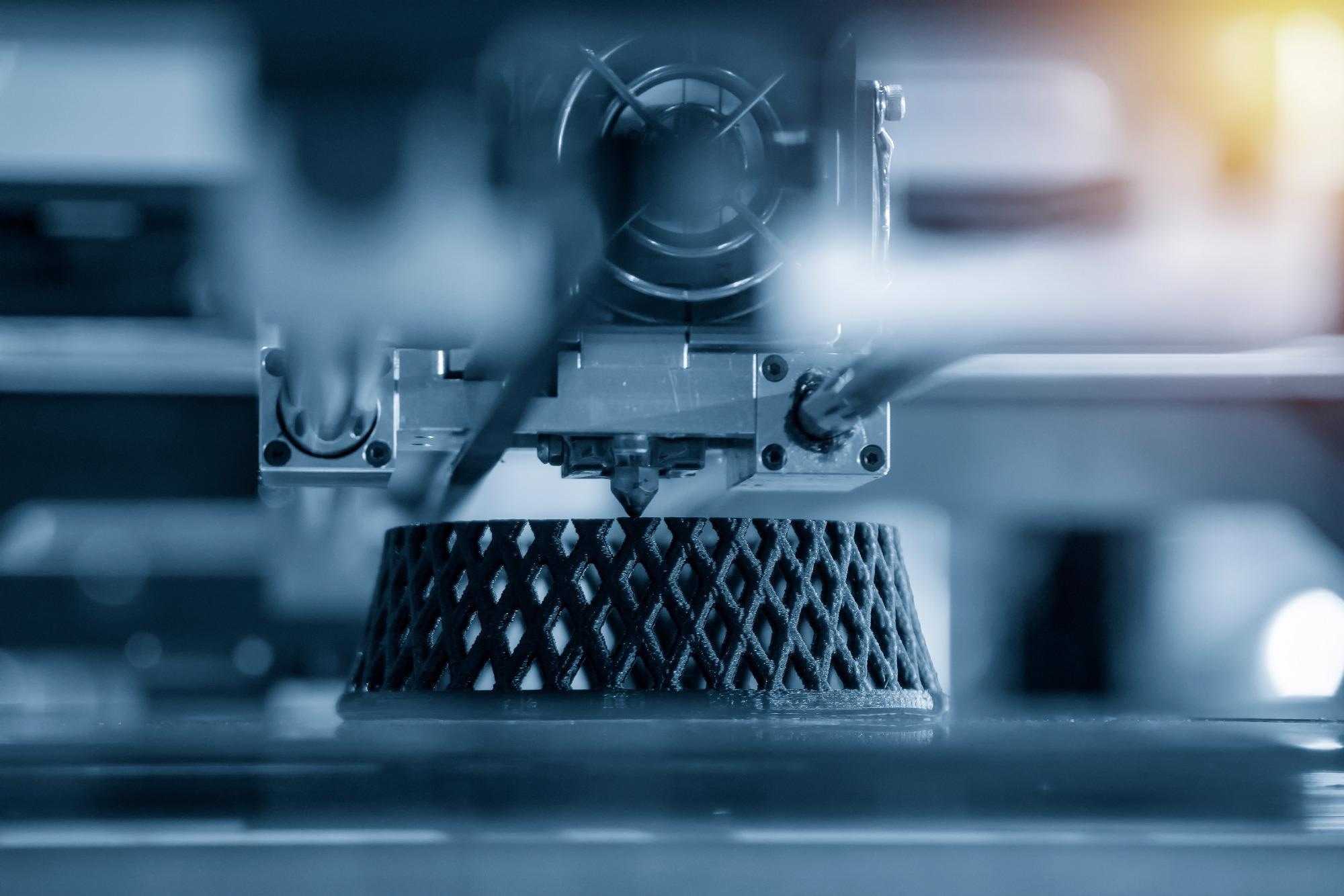

3. More applications of metal 3D printing: Metal 3D printing is not a new concept in India. Metal 3D printers are used in industries to mass-produce items made of aluminium, steel, and titanium. However, these machines are relatively expensive. More metal 3D printing applications will be seen in 2022 and beyond in the industrial sectors in India, especially in the automotive, aerospace, and healthcare industries. It will open up new possibilities, including prototypes, quick tooling, and functional component manufacturing. As a result, to stay competitive in global marketplaces, some large-scale steel and aluminium production companies will be seen partnering with 3D printing companies to cut down on overall production and operational costs.

4. Growing presence in the education sector: In 2022, 3D printing will also enter the education sector. Several educational institutions are teaching students about additive manufacturing by employing 3D printers. Students will have access to various designs and learn about different production processes early in their careers.

3D printing has already made inroads into various industries in India, including automobiles, healthcare, defence, aerospace, electronics, jewellery, footwear, sports, communication equipment, construction, and architecture. Other sectors will undoubtedly adopt the technology in the future years. However, there are other ways in which AM technology may assist Indian businesses in expanding.

A business that can scale, adapt quickly, and perform well in the face of changing needs has an edge over its competitors. In recent years, scalability has grown in importance since technology has made it easier to engage more clients and develop markets abroad. Manufacturing in India has its own set of issues, one of which is scalability. It all comes down to reactivity, adaptability, and optimisation via a singular production process. AM technology is suitable for scalability in business and can become your best ally if you are looking to improve responsiveness to changing market needs, flexibility in manufacturing, and reduce production costs. Let's look at the benefits and potential of scalability and how implementing it could improve your business standings: -

- Market-driven responsiveness- 3D printing for manufacturing allows businesses to be more responsive while remaining competitive. Thanks to a scalable and optimised production process, AM assisted businesses can meet ever-changing market demands with unrivalled lead times. Additive manufacturing is a cost-effective alternative for companies wanting to embrace more dynamic capabilities like on-demand production.

- Flexibility in production- The ability to adjust your product and business process is a great resource. 3D printing for business may help at every level of the organisation, whether dealing with inventory challenges caused by a product's uncertain demand or seasonality, an exorbitantly priced low-volume order, product customisation or design complexities. 3D printing enables manufacturers to avoid costly tooling costs and produce personalised things faster and more cost-effectively with the right manufacturing tools.

- Lowering production cost- 3D printing is a cost-effective and time-saving production technique that can significantly improve your manufacturing processes. With the adoption of 3D printing, things like optimising production costs, choosing the best manufacturing technique, improving the design, and rethinking the supply chain for raw materials and components used in manufacturing are a cakewalk.

Moving Forward

Although India's 3D printing industry can contribute to the country's next industrial revolution, it can only grow significantly in the future if the expected price reductions and higher market awareness are implemented. Other changes needed for the technology to succeed in India include simple design specifications, mass production compatibility, large-format object manufacturing capabilities, and prevention of market infiltration with poor-quality products, among others.